Nickel superalloys have revolutionized fashionable engineering with their exceptional capacity to face up to Extraordinary problems. amongst these, Inconel alloys—especially those equipped by leading inconel suppliers around the globe—jump out as a video game-changer for extremely demanding applications. From aerospace to chemical processing, these alloys promise remarkable overall performance, longevity, and resistance to tough operational environments. This blog site will investigate the unmatched Houses of superalloy bars, specializing in their high-temperature resistance, corrosion resistance, mechanical toughness, and Extraordinary longevity. By the tip, you will understand why several engineering professionals change to dependable inconel 718 stockists when dependability is non-negotiable.

Table of contents:

High-Temperature Resistance of Nickel Superalloys

Excellent Corrosion Resistance in severe Environments

Mechanical Strength of Superalloy Bars for Critical purposes

Longevity and sturdiness of Inconel 718 inventory

substantial-Temperature Resistance of Nickel Superalloys

Among the most significant Qualities of any substantial-general performance product is its capacity to deal with Extraordinary heat devoid of losing structural integrity. Nickel superalloys excel in this space, and Inconel 718, for example, is engineered to endure temperatures as substantial as 1300°file (seven-hundred°C). This Outstanding element makes it a desired choice for aerospace motor parts, warmth exchangers, and also other systems exposed to higher thermal tension. working with engineering optimized by leading-tier suppliers, these kinds of alloys keep balance in each cryogenic and elevated temperature settings. This house assures their suitability for purposes that demand prolonged operation less than rigorous heat, for instance turbines and warmth-taken care of products.

Outstanding Corrosion Resistance in severe Environments

Yet another defining characteristic of superalloys, which include nickel-based mostly inconel alloys, is their Extraordinary resistance to corrosion. Industries click here dealing with aggressive chemical agents depend on elements that will endure the degradation brought on by this kind of substances. Engineered with significant nickel, chromium, and molybdenum articles, superalloy bars fend off chloride pressure corrosion, oxidation, and acidic environments efficiently. Applications in chemical plants, maritime programs, and Electrical power sectors greatly utilize these products to boost program trustworthiness. a further edge is their suitability in both oxidizing and decreasing situations, ensuring these products retain prolonged-Long lasting toughness. For harsh problems, turning to set up inconel suppliers assures that finish merchandise satisfy exacting industry expectations.

Mechanical power of Superalloy Bars for important Applications

functionality is almost everything in engineering design, and superalloy bars lead With this arena. They show amazing tensile energy, yield Qualities, and Total toughness. For instance, perfectly-made inconel 718 bars—the steelwork of option for aerospace and gas turbine programs—are recognized for their robustness even though subjected to unimaginable force. The mechanical toughness is often a direct result of precise production procedures that include warmth remedies to improve the grain composition. for this reason, no matter if in higher-velocity wind tunnels or beneath crushing underwater pressures, superalloy bars assure dependable effectiveness with minimal have on and tear. Accessing these types of excellent from reputed inconel 718 stockists guarantees components satisfy functionality benchmarks.

Longevity and toughness of Inconel 718 inventory

For industries necessitating resources that stand the exam of time, inconel alloys redefine longevity. Their combination of corrosion resistance, warmth tolerance, and mechanical robustness minimizes don and failure fees, guaranteeing prolonged company lifestyle. This sturdiness is especially vital for aerospace, electric power technology, and chemical processing facilities, where by downtime incurs considerable economical losses. most of all, the composition of inconel 718 stocks supports minimum degradation, even if subjected to very fluctuating thermal and chemical stresses. Engineered to get steadfast about a long time of use, they continue to be a value-effective expenditure for industries prioritizing prolonged-term dependability.

From their unmatched significant-temperature resistance to excellent mechanical effectiveness, nickel superalloys like inconel solution the needs of cutting-edge industries. For providers trying to find excellence, partnering with renowned inconel suppliers or sourcing via an inconel 718 stockist guarantees results in deploying dependable components for engineering breakthroughs. planning to resource major-tier superalloy bars like inconel 718 for your personal next large job? Discover trustworthy, quality-confident choices and up grade your operations for unmatched general performance currently.

Emilio Estevez Then & Now!

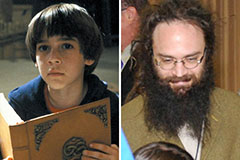

Emilio Estevez Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Jenna Jameson Then & Now!

Jenna Jameson Then & Now! Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!